We are now on our way to Cartagena and with the speed we are making, we nicely “out marched” the rain. Although the clouds were in the area but that is not so bad as clouds keep the temperature down and that makes being on deck very pleasant. And you can still sun bathe, even when it is a bit cloudy as there are still rays coming through that will produce a tan. Although quite a few guests shied away from the sun today as they got more than their fair amount yesterday.

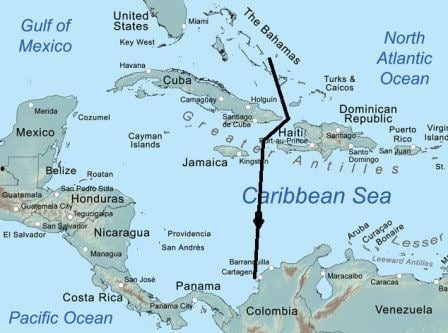

For most of the evening we sailed between the Bahamian Islands towards the south and then during the night we crossed the end of the old Bahama Channel, to reach the Windward Passage, located between Cuba and Haiti. We passed Cabo Maisi (the end point of Cuba) in the early morning and by the end of this afternoon we will be out of the Windward Passage and in the Caribbean Sea. This area is called the Jamaican Channel but we will not see Jamaica as we are too far to the East of it.

By that time we will be coming under the full influence of the Trade Winds and that should give us about 20 knots from the East. So windy on our Port Side and nice and gentle on our starboard side.

Continuing with my safety story of the last two days, the last thing is to explain are near misses in safety. As I do not want to create a panic on the internet; in safety we qualify a near miss as something that could have result in an accident but it did not. A bucket of paint started to slide but you caught it in time; somebody wants to stand on a box to change a lightbulb but somebody else saw it and got a step ladder. An electric socket had come loose but the danger was seen before somebody plugged a cable into it. etc. etc.

The challenge is to get everybody talking and provide examples of what they have seen or were involved in. We call these “learning events”. Something has happened, something did not go 100% right or something had the intrinsic potential to go wrong, but it was recognized and the situation was mitigated. To make it work, it has to start at the Top, with the leaders, and thus it has become an established feature on our ships to have each officer come forward, starting with the captain, to explain what in his/her work situation could have gone better. As the ships are a small world onto themselves, the word soon spreads around the crew and then the rest will follow.

The company is really encouraging everybody to do this and is asking each ship to provide every month 3 examples of near misses that they found, discussed, solved or learned a lesson from for the future. These are then shared fleet wide and slowly but steadily we see a reduction in the return of the same mistakes. One of the direct results is, that our accident free days are going up. We define anything that needs more than a plaster to be an accident, (that is about the only thing the crew doctor does not write a report about) and thus is it is not easy to stay on zero. But ships with 800 crew or more are now reaching 300+ days without anything happening at all. Safe work with a moving ship and so many cooks with knives and so many engineers in machinery environments it is not as easy as on the shore side and so we are really pleased with the results. But everybody is keeping focused; as our friend Murphy has a nephew on every ship and they simply hate good safety records and mistake free environments. So the safety training, the safe work planning, the safe work execution and the “learning experiences” continues and will do so in the future.

I am honored to play a little role in this all, apart from the inspecting, by training and teaching. Due to my unique position as Travelling Master I can compare the ships while I rotate around and can pick up and pass along good practices and little changes which can make a large difference in a chain of events.

So tomorrow we are at sea again, and looking at the weather chart we might lose the cloudiness later in the day but could get an isolated shower during the night or early morning.

October 24, 2016 at 12:12 pm

Captain Albert

I spent a full career in the United States Air Force and in addition to rigorous training we had periodic inspections from Headquarters. As Travelling Master you are providing training on a range of issues and also giving the Captain in Command a fresh set of eyes. My question is: in addition to what you do does HAL Hq send out inspection teams to take a look at the fleet?

Regards,

Roger T

October 24, 2016 at 8:09 pm

Thank for (still) reading my blog.

There are a lot of inspections, called audits, that come to the ship. Every two years there is a 7 day audit from Carnival Corporation Maritime department which goes to all the 112 cruiseships under the umbrella. Then there is the visit of the Designated Person from our head office who stays for a few days, then there are corporate trainers who also do quality control and there is the fleet captain who does the bridge quality assurance. Then the Vp’s and the President shows up on occasion and they all have their standards and input. Outside of that we have USCG , port state in other countries, Lloyds, flag State, the list just goes on and one. I am standing on the other side of the table and try to help make sure the ship is ready to deal with all of it in the best way possible.

Best regards

Capt. Albert

October 24, 2016 at 5:14 pm

Hi Captain:

In referring to on board indidents/accidents as observed by the ship’s doctor I presume you meant the word “pleister” , a word I remember from my childhood as the Dutch word for “band-aid” which then again is a brand name thing generically referring to “adhesive bandage” Oh well, didn’t mean to make a bid deal out of if. I love your safety related posts……Ruud

October 25, 2016 at 8:12 am

A huge ‘Well done’ to all HAL crews for their safety record. Having worked almost all my working life in the airline business I know what its like with audits coming from all areas! I always feel safe when sailing on a HAL ship.