Spring might be in the air as we had another sunny and hazy day a today and you could walk outside without a coat on. The coverall and helmet was sufficient to “brave” the weather. It also makes the shipyard works happier as they can do their dusty work outside.

A long queue entering the HAL ware house to comply with the labor law of daily logging the working hours.

And the crew was very happy as we are still living in two places and we have to leave the ship regulary. Some of the offices are still off the ship as the computer network is not yet fully up to speed. This means for the crew there is a daily pilgrimage to the shore side office of the Crew Officer to log in their hours from yesterday. Then it is in parade back to the ship for receiving the job orders for the coming day.

While the weather gods are keeping things dry, it is now the shipyard who are making things wet. The promenade deck with the lifeboats has been completed and they have started hosing down the bulkheads and the boats. Then there will be some more touch up with paint again and then all the protective covering will be removed from the lifeboats. Everywhere the lifeboats are touching the davits arms there is still padding and plastic in place.

The lifeboats are already in use as the 2nd officer Training has organized a Lifeboat Boat Assistant course for those who are part of the lifeboat crew. The Commander and Asst. Commander get official training and certification shore side and need on board only refresher training. For the other lifeboat crew, in depth training is given on board and they also will receive a certification. As the crew has been coming from all the other ships they were not necessary involved with lifeboats there and thus they still have to go through this training. It takes about 14 days with theoretical and practical, followed by an exam.

Finally the dance floor in full view. It will still need some TLC before the first dancers can twirl away.

Today most of the protective material was removed in some of the lounges which now are ready for final cleaning and putting in all the Hal material. Thus the floor of the Queens lounge was revealed which will now be the focus of attention for the polishers. Billboard and Lincoln Centre are now completely clear and the Grand Dutch Café is nearing completion.

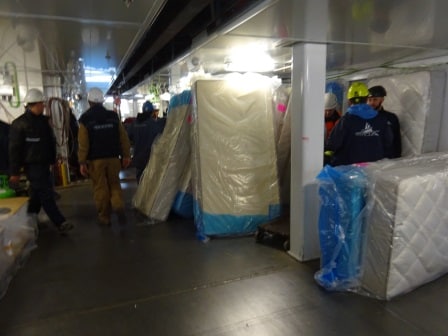

Housekeeping has taken over the cleaning of the shops. The cleaning ladies from the ship yard have now started on the corridors and the Shop Staff are busy with getting boxes on board.

In the show lounge, officially called The World Stage, things went differently this morning. Unlike in the past days when they tried to switch on as much as possible to see if it all worked, today they switched off as much as possible. Better said they switched off everything. It was a sort of “black-out morning”. Purpose was to check if the whole lounge was indeed black and no light was coming from anywhere to disturb the show. Luckily most of us now have a cell phone with a flash light option and we did not come un-stuck when suddenly all the lights went out, and then out again. But I can guarantee, it was dark, pitch dark, leaning towards pitch black.

That the ship is nearing completion came with a strong hint today; the plants and flowers came on board. Holland America is famous for having more greenery on board than with any other cruise company and that fact was re-emphasized today. It made us feel at once a bit more ship-like. Some plants have already been put in place and the rest will follow shortly. It will really bring the ship alive. I am personally waiting to see how green the Culinary Arts Centre will be as there is a whole wall section devoted to the on board growing of all sorts of herbs. Luckily garlic does not smell much when it grows otherwise it would be an interesting area to walk through. Or is garlic not an herb??

As explained yesterday, with the pyramid example, today there was not much delivered or cleared away from other areas. Some lounges where having a heady mix of carpenters, electricians, tile setters, cleaners and other technical folk trying to do their job all at the same time.

The Back Office of the Front Office is already in full swing. The Guest Relation Manager is preparing with her team for the first voyage.

So I finish today with another picture of behind the scenes; our bakery is working! And it is churning out fresh bread and desserts for breakfast, lunch and Dinner. But our Baker was not a happy man this morning, just while his dough had risen, somebody switched off the power to the Oven. His whole team had to run and move everything upstairs to the warming cabinets in the main Galley. But he got it done on time and we had excellent rolls for lunch time.