With the cruise industry being so popular and there only being three major shipbuilders (with several subsidiaries) at the moment, shipyards are churning cruise ships out as if they are building cars. This means there is the advantage of cost reduction through standardization but also the challenge of still delivering a ship which can be identified with the company that ordered it and is hopefully still unique among all the other ships coming out around the same time. Holland America with its new building program is of course right in the middle of it.

The standardization part is taken care of by Carnival Corporation. They have a large office in each Fincantieri shipyard and these people ensure every ship is built to not only the same legal standards but also the same company – corporation- standards. Where possible the same equipment and material is used. Thus a bow thruster in a Carnival ship will be the same as a bow thruster in a Holland America ship. This does not have any influence on the guest experience and thus it does not need to be brand specific. The same goes for a myriad of other things. For the ships interior and the operational side things differ and then the company’s needs are built into the specification. Interiors are unique and it is up to each company to use a preferred designer. The actual installation work is carried out by sub – contractors and they can be arranged by the yard/carnival office but they can also be company preferred. We have now contractors at work, who both work on the Koningsdam and on the Seabourn Encore which is docked behind us.

The Queens lounge as seen from Balcony level. It still looks a mess but it only needs the protective covers to be taken away.

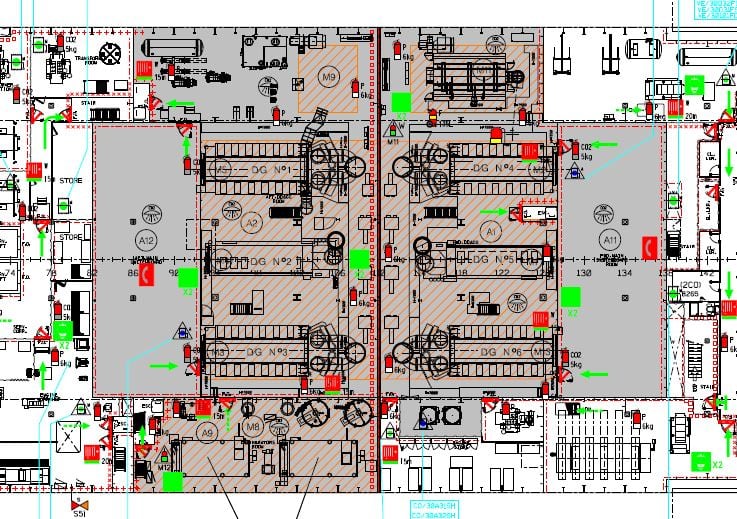

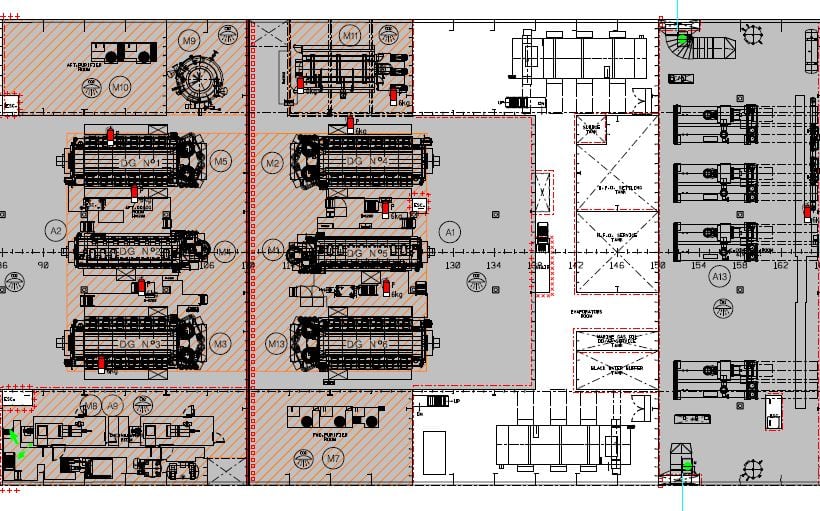

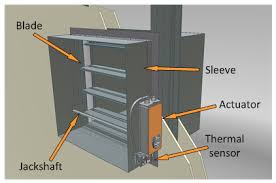

The big puzzle is now for the shipyard, for Carnival office and for the Hal people at the yard is how to get all the work done in the right sequence. As long as only the hull is being constructed, it is not as complicated but as soon as the fitting out starts it does get complicated. A simple thing as installing a door will involve several different companies.

A. somebody builds the frame work: B. somebody delivers the door: C. somebody installs the door: D. somebody installs the door lock: E. somebody installs the safety notice on the inside of the door. F. somebody installs the door number, and during the whole process there are several somebodies who are constantly checking is it is being done and if it is being done according to specifications and without damage. ……………. And that is only something as simple as a door.

What is almost finished is the Jewelery shop. It still needs some cleaning and the inventory and we are ready for business.

This all results in constant meetings and questions (everybody on their cell phones!!!) in order to streamline the work as much as possible and to avoid parties being in each other’s way. It is not unknown for one contractor to barge over or through a freshly painted area or new installed tiling belonging to another contractor. All the officers and staff assigned to the new building are in between this all, as in the end they have to check if everything is really “their ship” and if it works and if they can work with it.

As a result of all these conflicting interests and requirements some areas are further towards completion than others. In the end it will all come together but at the moment it is not yet visible. Then there are some area’s which look incomplete but what is only missing is the lighting, the props and the furniture.

Getting things together is taking on an even greater urgency as tomorrow we are supposed to go on board and start living on the ship. March 10 is stipulated in the contract and the yard wishes to stick to the contract. Cancelling at the last minute is really not an option as the leases for the apartments expire and for the hotels arrangements end and all the new crew coming to the ship will then go directly on onboard.

So tomorrow is the big day when the ship goes from a building site to being a passenger ship, although the passengers are for the moment officers and crew. The weather gods seem to favor us as tomorrow is predicted to be a sunny day with temperatures around 14oC / 58oF.